A large-scale additive manufacturing (LSAM) service will be added to our services and ramped up during the last quarter of 2023. The used technique, granulate-based Fused Granulate Fabrication, is significantly faster than filament-based 3D printing methods, enabling a fast and cost-efficient method to print larger objects. Benefits compared to traditional manufacturing methods are, among other things, efficient manufacturing without molds, production of customized products, a wide range of suitable materials including bio-based and recycled materials as well as very little waste. LSAM transforms the way of producing large pieces in various industries. Possible applications are for example furniture, parts for vehicles, boats, and ships, theater and movie decor, industrial molds and jigs as well as scale models.

A large-scale additive manufacturing (LSAM) service will be added to our services and ramped up during the last quarter of 2023. The used technique, granulate-based Fused Granulate Fabrication, is significantly faster than filament-based 3D printing methods, enabling a fast and cost-efficient method to print larger objects. Benefits compared to traditional manufacturing methods are, among other things, efficient manufacturing without molds, production of customized products, a wide range of suitable materials including bio-based and recycled materials as well as very little waste. LSAM transforms the way of producing large pieces in various industries. Possible applications are for example furniture, parts for vehicles, boats, and ships, theater and movie decor, industrial molds and jigs as well as scale models.

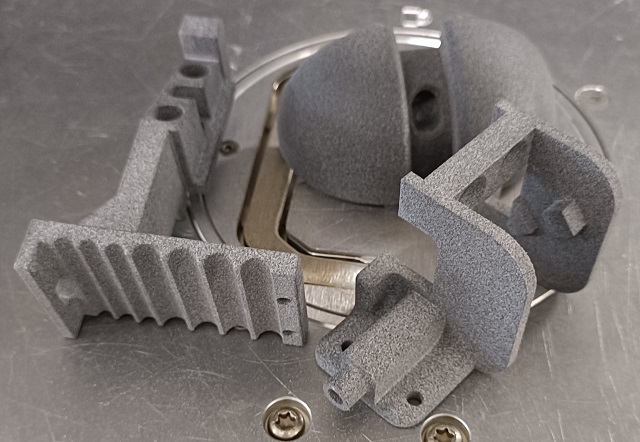

3DTech’s solution

Technology: Fused Granulate Fabrication (FGF), known also as Granular Extrusion and Fused Particle Fabrication

Build Volume: 1500 mm x 1000 mm x 990 mm in pilot phase (later max 2000 mm x 1500 mm x 1000 mm)

Nozzle options: 1 mm, 3 mm and 5 mm

Support material: Same material as the printable object. Mechanical removal.

Limitations: Applicable only for medium-sized and large objects. A need for a support structure should be avoided, or kept at a minimum when planning an object’s geometry. The printing layers are visible, so, depending on the object, the surface may require post-processing.

The process will be piloted with selected customers during the last quarter of 2023. The aim is to find models, that don’t require a support structure, or they need it very little. Examples of possible applications are large molds, design furniture and décor, and large prototypes.

Available materials at the start

FGF PIPG Glassfiber (19%), PIPG Glassfiber (30%)

- PIPG (recycled postindustrial PET-G) is filled with 19%/30% glass fiber to improve impact strength and tenacity.

- Good general-purpose material for applications like industrial molds, décor, furniture, and prototypes

- FGF PIPG Glassfibre 19% datasheet

- FGF PIPG Glassfibre 30% datasheet

FGF PIPG FR UV

- V0-certified flame retardant and UV-stabilized version of PIPG with 10-20% of glass fiber.

- FGF PIPG GF FR UV datasheet

UPM Formi 3D Biocompocite

- A biomaterial mix of cellulose fibers and PLA

- 100% recyclable

- 3D printed parts can be post-processed by conventional wood post-processing methods

- Suitable for applications like furniture, molds (e.g. concrete casting, vacuum infusion), art and decor, and prototyping

- UPM Formi datasheet

- References

More materials will be added when needed later.